Best Filter Press Manufacturers in Chennai

Your trusted Partner for a precised filtration and a cleaner future

We accredited by

Leading Filter Press Machine Suppliers in Chennai

GTS Enviro India Pvt Ltd is the South Indian Dealer/Channel partner of Panama Engineering Company and the finest manufacturer of filter presses in all capacities suitable for all standard and heavy-duty performance levels. With 24+ years of expertise in this industry, we take pride in supplying cost-effective dewatering equipment that prioritizes sustainability and environmental responsibility with the latest technology.

Explore our range of premium filter press and its parts designed for optimal performance and durability. Contact us today, we are the customized filter press manufacturer in Chennai supplying 100% quality filter presses at an affordable price for your esteemed industry.

Types of Filter Press We Manufacture in Chennai

Fully automatic filter press system with auto cloth washing carrier

We are the prominent Automatic Filter press systems suppliers in Chennai offering high-end degree of dewatering, economical in filtration system that gives more the cycle time per day and more dewatering of feed sludge. The fully automatic filter press is a fully advanced PLC programmed system with plate shifter mechanism and cloth washing carrier that increase the filtration time.

High-level of security

Maximum Versatility

Trouble-free operation

Automatic Membrane Filterpress System (Membrane Squeeze type)

The filter plates which are used in our membrane filter press are designed for unique applications. We design, manufacture, supply diaphragm/membrane squeeze filter press plates that will give excess removal of Sludge. Get the high quality membrane filter press systems with customized options from our leading suppliers in Chennai.

High-level of security

Short working cycle and high efficiency

Good filtering performance

PP Recessed plate hydraulic operated filter press system.

We manufacture the hydraulic operated filter press systems in Chennai with customized options that includes PP Recessed plate. The plate and frame press are the most fundamental and the conventional type of filter press. The modern version of a filter press uses plates that have recesses and are therefore called recessed chamber filter presses. The frames act as clamping holding supporting part, and will use a hydraulic cylinder and pump to open and close the press.

Can achieve very low cake moisture content

Minimal energy consumption

High Processing capacity

Semi Automatic Camshaft Filter Press System

We construct top-quality Semi-automatic filter press in Chennai for effective process control, moving from simple mechanisms to automatic systems for ease of day-to-day operations and filtered sludge separation that works faster than manual. Our semi-automatic filter press system offers a high degree of configuration with maximum flexibility and flawless filtration.

Space-saving Equipment

Fulfill the special safety standards

Simplified operation

High-Quality Filter Press Spare Parts and Accessories Manufacturer in Chennai

Top-notch Industrial Filter Press Provider in Chennai

Being the most trusted manufacturer and dealer in Chennai, GTS Enviro India Pvt Ltd is equipped with a team of engineers, technicians, and the necessary infrastructure for the successful installation of Filter press dewatering Systems. Whether you need spare parts, services, repairs, upgrades, or modernization of your filter presses, we are the one-stop solution for all your filtration needs.

We make quality filter press parts in all sizes and capacities suitable for various industrial applications. As a reliable filter plate manufacturer in Chennai, we offer a replacement for a wide range of filter plates and other accessories with 100% premium quality spare parts. Our customized filtration solutions are designed to improve the equipment’s reliability and longevity, thus helping you optimize the performance of the filter press according to your specific industry.

Why

choose our service?

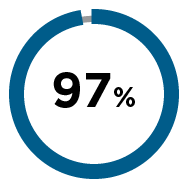

GTS Enviro India Pvt Ltd is the Trusted OEM in Chennai for Filter press with high-quality materials and customized design. We supply advanced systems with advanced technology to treat wastewater in different industries and offers flawless performance at affordable price.

Application of Filter Press in Various Industries

We are the most prominent and reliable automatic filter press manufacturer in Chennai, Tamil Nadu supplying machines for a wide range of industries with multiple configurations and high filtration velocities. Our filter press in Chennai has a broad range of options that are available with numerous design and operating modes from manual to fully automatic that can be used for extensive applications. Whether you need plate and frame, hydraulic, automatic, or membrane filter presses, we supply efficient equipment for the finest and high-degree of separation to meet the market demands in the modern filtration industry.

Discover Frequently Asked Questions

Top Filter Press Manufacturers in Chennai